Cradle of Innovation

The dialysis network

What do virtual reality simulations, laboratories for measuring electromagnetic interference, rapid prototyping of machine components, and intercultural usability tests of prototypes have in common?

They all play a key role when it comes to developing and optimizing dialysis treatment. Together with all other relevant areas of development, they will soon be housed under one roof – in Fresenius Medical Care’s new Technology Center in Schweinfurt, Germany. The building has the size of a soccer field and will accommodate the more than 1,200 employees already working on the site, a third of them in research and development. And the number is increasing.

“In the new Technology Center, we will develop innovative solutions for the benefit of our patients. The focus is on close networking with clinic staff, patients, service and production.” says Dr. Olaf Schermeier, member of the Management Board responsible for research and development at Fresenius Medical Care.

Improving the patient's life

The objectives and approach of the new Technology Center are clearly delineated: to continuously improve the daily lives of patients with end-stage renal disease, develop products for an improved quality of life, minimize side-effects, generate knowledge more effectively worldwide, and bring innovations to production by the shortest route possible. In other words, to ensure that patients benefit from progress faster.

This is a process that has long been established also beyond Germany’s borders: Fresenius Medical Care operates development sites worldwide from France and Italy to countries further afield such as Mexico and China, with 825 employees in research and development alone. Interdisciplinary teams across locations have been a reality for some time now, and networking across time zones is part of everyday work. In the future, all these strands will merge at the Technology Center in Schweinfurt, in a modern new building that embodies the Company’s interdisciplinary working culture.

Closely coordinated development

“In dialysis technology, even the tiniest improvements can have a significant positive impact on patients’ daily lives. In this respect, closely coordinated development work that is advanced on a global scale is essential to Fresenius Medical Care,” says Johann Brede, the manager responsible for the Technology Center. “We are shortening our lines of communication and facilitating professional exchange to be able to react more quickly worldwide.”

Topics range from improving individual components such as water treatment for dialysis to performing digital fine-tuning of equipment. For example, software developers are working on evaluating signals that show how blood properties change during the dialysis treatment.

As dialysis expertise involves a wide range of disciplines, a clash between the different working methods applied in the various specialist departments is something that is expressly desired. A dialysis machine incorporates knowledge from the fields of medicine, electronics, mechanics, physics, chemistry, and physiology, as well as production technology, process engineering, and IT. Catering for regional specifics is an increasingly important aspect of development work.

What are the implications for the design of a touch screen for a new dialysis machine if staff in Germany are used to and want no-frills displays, while in Asia, more playful ones with pictures are the cultural norm? The answers to questions like these are explored by international teams that collaborate on specific projects. That way, effective solutions can also be found more quickly for growth markets with specific regional needs.

No lifestyle product

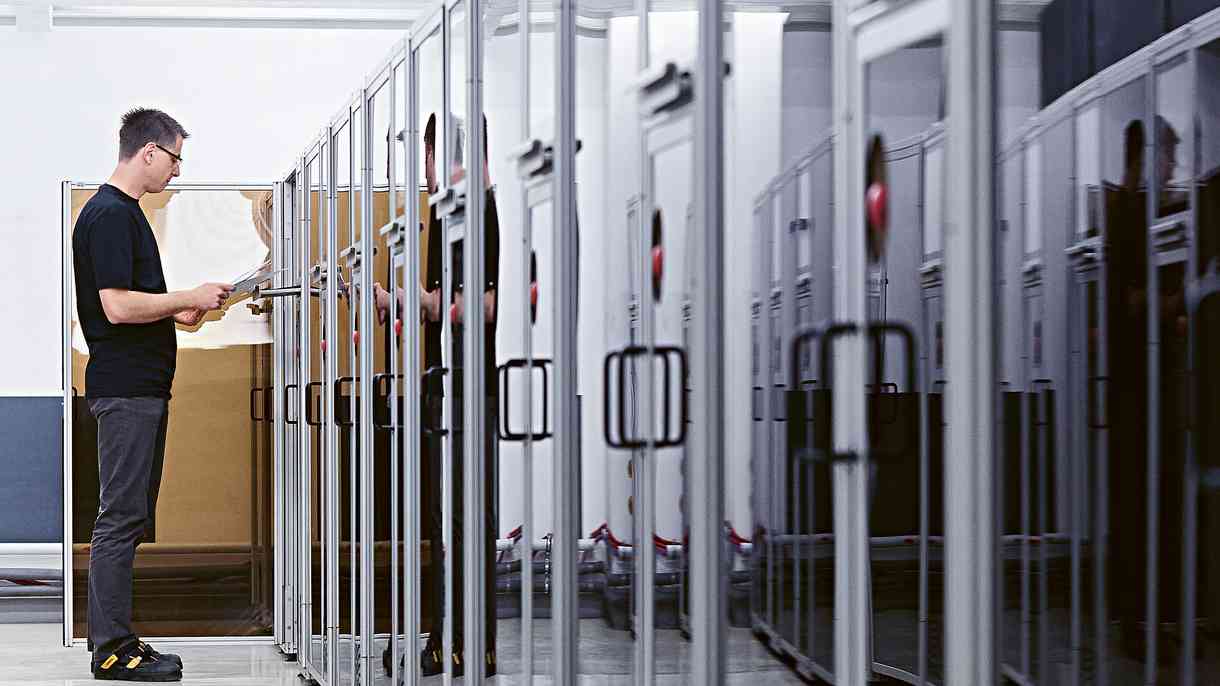

“A medical product is not a lifestyle product. If the screen fails on a cellphone, it’s annoying, but it must not happen to a dialysis machine while a patient is connected,” says Johann Brede. In so-called usability labs, authentic clinic environments can be simulated to find out how self-explanatory the devices actually are for specialist staff.

“We can gain valuable findings by testing how application consultants from Germany, India or Australia handle newly developed devices like the dialysis machine 6008, for example.” In future, it will also be possible to optimize the operation of devices by means of virtual reality tests.

Building progress

In the laboratories and test rooms in Schweinfurt, the devices are constantly available and placed nearer to the project teams than ever before. Software developers and mechanics work closely together assisted by rapid prototyping, a process that allows new components to be produced on a 3D printer and immediately installed on the product and tested.

Interference from cell phones for instance, an increasingly common phenomenon in the mobile age, is simulated and analyzed in the electromagnetic compatibility labs. And in the verification and test centers, modules and machines are subjected to long-term tests to ensure their long service life and durability.

Fresenius Medical Care operates over 40 production facilities, manufactures more than half of all dialysis machines in the world, and performs around 48 million dialysis treatments a year. Every patient has highly individual requirements in terms of their treatment. The Technology Center will be the central interface – between customer preferences, user priorities, development, and production – a cradle of innovation.