Designed to dialyze. Built for cardioprotection.

FX classix

Key features

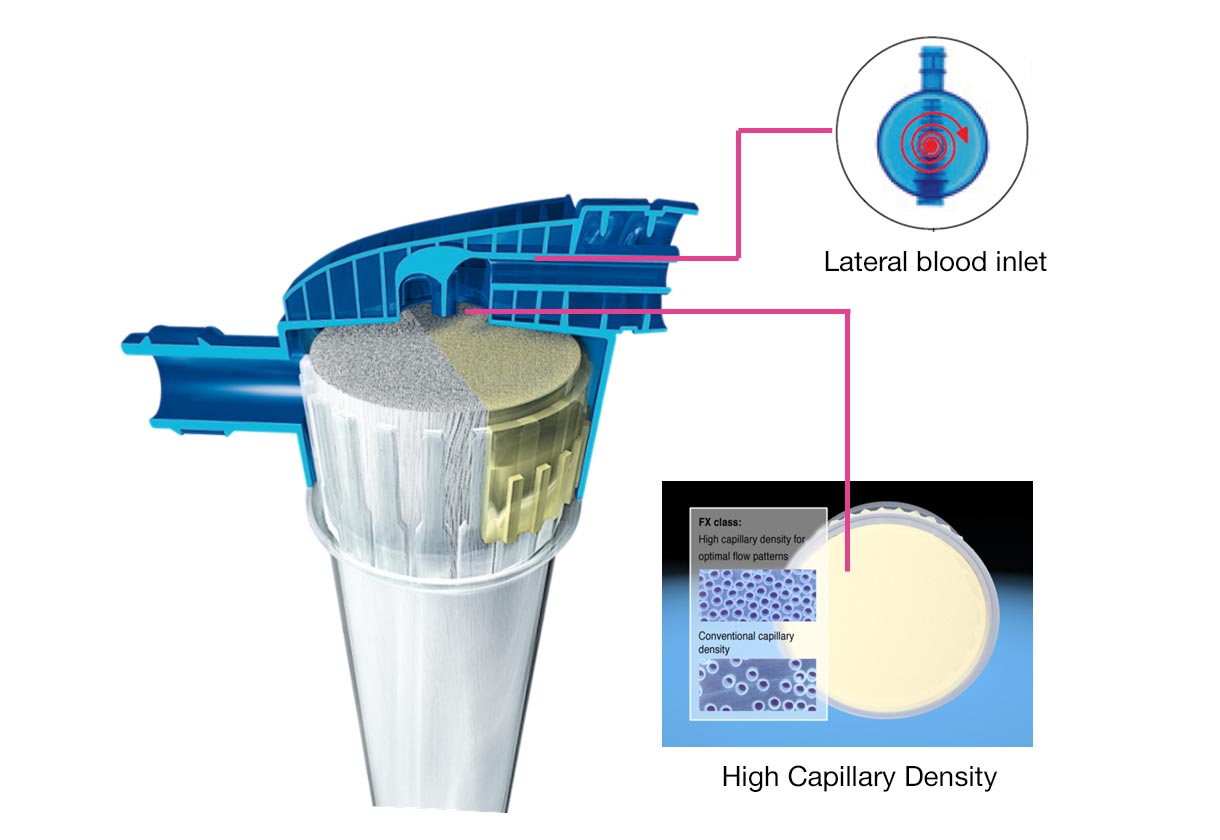

Optimized blood flow conditions

- The lateral blood-inlet port provides a homogenous blood flow in the dialyzer header, preventing stagnation zones. The design minimizes the risk of kinking, contributing to improved safety

- A high capillary density leads to a more even distribution of the fibers. This ensures a homogenous distribution of the incoming blood flow into each fiber in the bundle

Homogeneous dialysate flow for better clearances

- The pinnacle structure at both ends of the polypropylene housing together with the potting technology provides an even, radial flow of the dialysate around the individual fibers of the bundle

- The undulation of the hollow fibers prevents dialysate channeling and, thus, enhances the performance of the dialyzer. The higher packing density of the fiber bundle together with the undulation of the hollow fibers enables a uniform dialysate flow within the whole cross-section of fiber bundle

The FX-class housing design

The FX-class design

Dialyzer weight

Dialyzer weight is a crucial factor not only in logistics but also in waste management. The housing of FX-class dialyzers is made of polypropylene. In comparison to the widely used polycarbonate it is much lighter with the result that FX-class dialyzers weigh around half as much as most dialyzers.

| Dialyzer weight is a crucial factor not only in logistics but also in waste management. The housing of FX-class dialyzers is made of polypropylene. In comparison to the widely used polycarbonate it is much lighter with the result that FX-class dialyzers weigh around half as much as most dialyzers. | |

|---|---|

| FX 60 classix | 107g |

| FX CorDiax 60 | 107g |

Weight of FX-class dialyzers

The benefits of INLINE steam sterilization

| No chemical residuals | No need for gamma sterilization – high energy ionizing radiation can degrade and alter the material chemistry. |

| Low rinsing volumes |

Minimal preparation time – since dialyzers are clean on arrival, rinsing times prior to use are substantially reduced. |

| Less rinsing – lower costs | Lower rinsing volumes mean reduced preparation times and costs. |

Technology

Better clearance through nanotechnology

Conventional pores

Helixone pores

When FX-class dialyzers were introduced into the market, an innovative spinning technology had been developed to produce its Helixone membrane. The so called Nano Controlled Spinning (NCSTM) technology allowed the production of highly-defined pore structures. Opposed to the previously produced conventional pores which were rugged and uneven in shape, the pores at the inner layer of the Helixone membrane are smooth and cylindrical. This reduces the resistance of the molecules when travelling through the pores and therewith allow for enhanced removal.

Optimized pore spectrum through nanotechnology

All Helixone membranes offer optimized sieving properties as the pore size distribution has been tightened compared to previously produced membranes as used e.g. in the F-series. The average pore size is larger compared to F-series dialyzers and the variance in pore sizes is smaller. This results in a better selective permeability for middle molecules, i.e. a more favorable β2-m / albumin sieving proportion.

INLINE steam sterilisation

Benefits of the INLINE steam sterilization process

- Highly pure, sterile and pyrogen-free dialyzers without any potentially harmful residuals from sterilization

- Biocompatibility of membranes remains unaffected from sterilization

- Optimized use of resources due to low rinsing volumes: Only 500 mL is required

- Minimized risk of blood leakages and fiber ruptures due to 100% fiber integrity testing

- Dry dialyzers with minimized risk of contamination due to microbial growth

Fibre integrity testing

All dialyzers have to pass the bubble point test. Here, sterile air is pressed into the dialysate compartment while the blood compartment contains sterile water. If any leakages were present in the membrane, air would pass through the membrane and create bubbles. This integrity test minimizes the risk of fiber ruptures and therewith the risk of blood leakages.

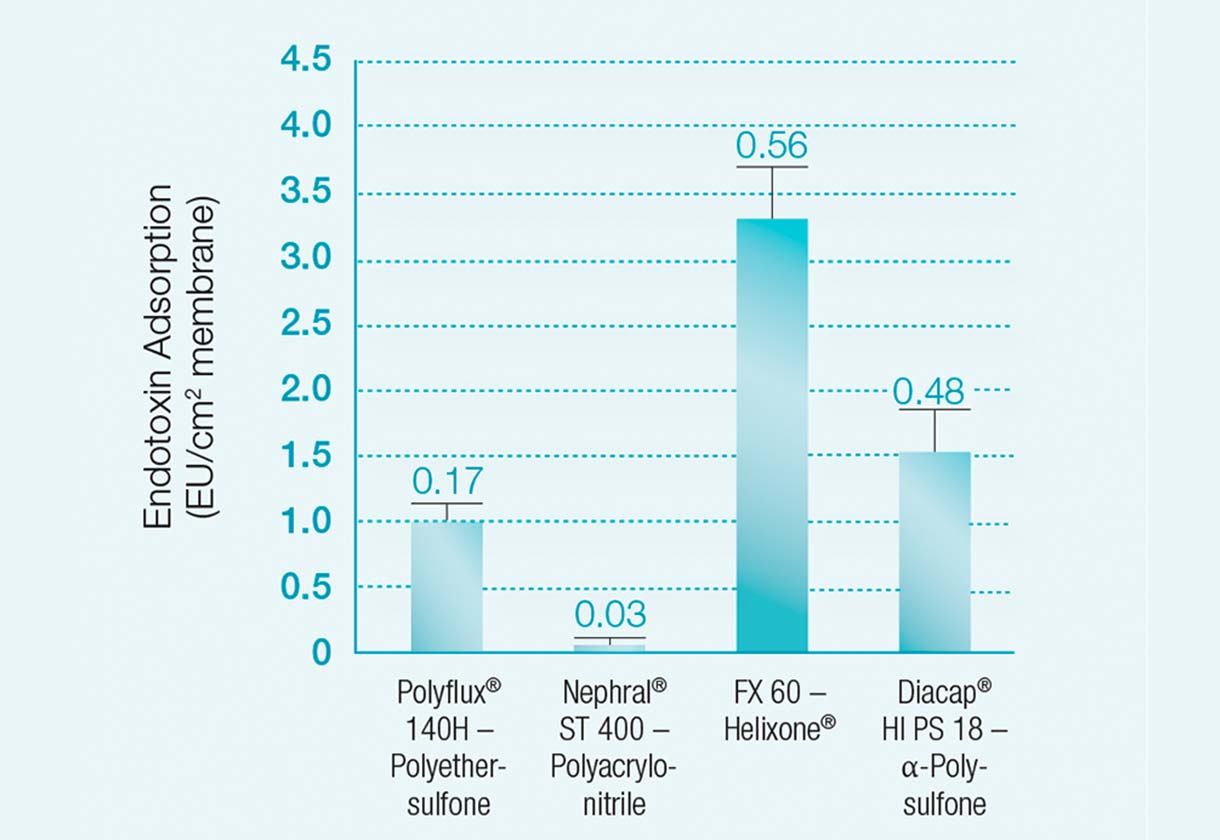

High endotoxin retention capacity of Helixone

Weber et al. (2003) compared endotoxin adsorption capacity of different dialyzers.

The Helixone membrane of a FX 60 dialyzer had a higher endotoxin adsorption capacity compared to:

- Gambro‘s Polyflux 140H - Polyethersulfone (Polyamid S)

- Gambro‘s Nephral ST 400 - Polyacrylonitrile (AN69ST)

- B.Braun‘s Diacap HI PS 18 - Alpha- Polysulfone

Performance data

| FX classix High-Flux dialysers | FX 50 classix | FX 60 classix | FX 80 classix | FX 100 classix | |

|---|---|---|---|---|---|

| Clearance (QB = 300 mL/min) | Molecular weight (Dalton) | ||||

| Cytochrome c | 12,230 | 55 | 74 | 89 | 100 |

| Inulin | 5,200 | 72 | 95 | 113 | 122 |

| Vitamin B12 | 1,355 | 137 | 162 | 185 | 201 |

| Phosphate | 132 | 204 | 225 | 244 | 253 |

| Creatinine | 113 | 224 | 243 | 259 | 264 |

| Urea | 60 | 253 | 266 | 279 | 280 |

| Clearance (QB = 400 mL/min) | |||||

| Cytochrome c | 12,230 | 76 | 92 | 105 | |

| Inulin | 5,200 | 99 | 119 | 129 | |

| Vitamin B12 | 1,355 | 175 | 202 | 222 | |

| Phosphate | 132 | 252 | 279 | 291 | |

| Creatinine | 113 | 277 | 300 | 309 | |

| Urea | 60 | 312 | 334 | 336 | |

| Ultrafiltration coeff. (mL/h x mm Hg) | 27 | 38 | 53 | 68 | |

| Sieving coefficients | |||||

| Albumin | 66,500 | < 0.001 | |||

| Myoglobin | 17,053 | 0.1 | |||

| β2-microglobulin | 11,731 | 0.7 | |||

| Inulin | 5,200 | 1 | |||

| In vitro performance: QD = 500 mL/min, QF = 0 mL/min, T = 37°C (ISO8637). Ultrafiltration coefficients: human blood, Hct 32 %, protein content 6 %. | |||||

| Membrane material | Helixone | ||||

| Sterilisation method | INLINE steam | ||||

| Housing material | Polypropylene | ||||

| Potting compound | Polyurethane | ||||

| Units per box | 24 | ||||

| Effective surface (m²) | 1.0 | 1.4 | 1.8 | 2.2 | |

| K0A Urea | 866 | 1,068 | 1,394 | 1,429 | |

| Priming volume (mL) | 53 | 74 | 95 | 116 | |

| Article number | F00002385 | F00002386 | F00002387 | F00002388 | |

Related content

1 Weber V. et al., Blood Purification (2003); 21: 365.