HighVolumeHDF® as standard.

FX high-flux and FX low-flux dialyzers

Key features

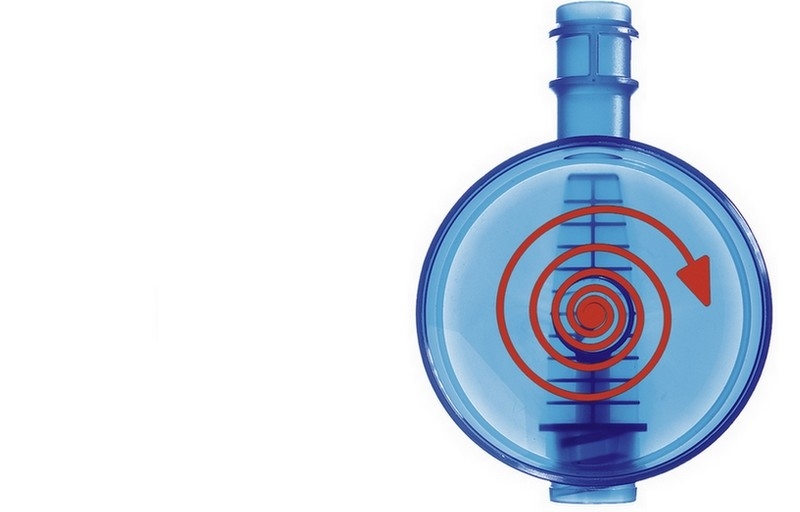

Radial dialyzate flow

- The pinnacle structure of the polypropylene housing ensures a uniform dialyzate flow around the entire fiber bundle

- A high packing density of the fiber bundle and a special wavy fiber structure to avoid dialyzate channeling

- Combined these features enable the constant performance of all FX dialyzers

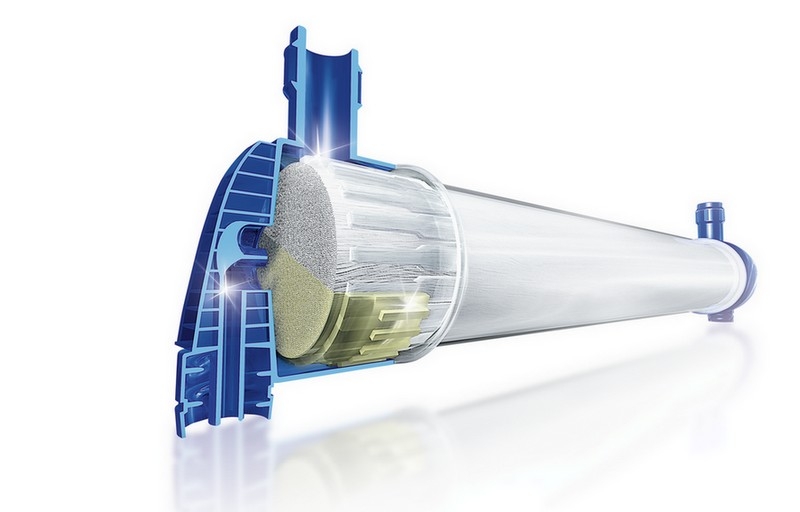

Optimum fiber dimensions

- The reduced inner diameter and wall thickness of the fiber increase the internal filtration and minimize diffusive resistance

- A significant increase of both the diffusive and convective clearances is therefore achieved, allowing the efficient removal of a broad spectrum of uraemic toxins

Technology

Helixone® — the advanced polysulfone membrane

- Nanotechnology membrane fabrication procedures (Nano Controlled Spinning Technology, NCS™) provide Helixone® with a highly-defined pore structure and distribution at the innermost, separating region of the membrane1,2

- Unlike conventional pores which were rugged and uneven in shape, the pores at the inner layer of the Helixone® membrane are smooth and cylindrical

- This reduces the resistance of the molecules when travelling through the pores and allows for enhanced removal

Helixone® has been specially designed to meet the demands of both low-flux and high-flux therapies:

- More even distribution of pores

- Estimated increased average pore size of 1.8 nm (low-flux) and 3.3 nm (high-flux)

- Increased performance per unit of surface area

INLINE steam sterilization – purity ensured

No chemical residuals. Low rinsing volumes. Lower costs.

INLINE steam sterilization – the benefits

- Highly pure, sterile and pyrogen-free dialyzers without any potentially harmful residuals from sterilization

- Biocompatibility of membranes remains unaffected from sterilization

- Optimized use of resources due to low rinsing volumes: only 500 mL is required

- Dry dialyzers with minimized risk of contamination due to microbial growth

Performance data

FX low-flux dialyzers

| FX low-flux dialyzers | FX 5 | FX 8 | FX 10 | |

|---|---|---|---|---|

| Ultrafiltration coefficient (ml/h x mmHg) | 8 | 12 | 14 | |

| Clearance: QB: (200ml/min) | ||||

| Urea | 180 | 191 | 193 | |

| Creatinine | 165 | 178 | 181 | |

| Phosphate | 141 | 160 | 170 | |

| Vitamin B12 | 88 | 107 | 121 | |

| Clearance: QB: (300ml/min) | ||||

| Urea | 228 | 254 | 261 | |

| Creatinine | 200 | 225 | 231 | |

| Phosphate | 164 | 194 | 210 | |

| Vitamin B12 | 94 | 120 | 138 | |

| Clearance: QB: (400ml/min) | ||||

| Urea | 293 | 303 | ||

| Creatinine | 252 | 260 | ||

| Phosphate | 213 | 233 | ||

| Vitamin B12 | 126 | 146 | ||

| The in vitro performance data were obtained with QD = 500ml/min: QF = 0ml/min; T=37°C (ISO8637) The ultrafiltration coefficients were maintained using human blood, Hct = 32%, protein content 6% |

||||

| Effective surface area (m²) | 1.0 | 1.4 | 1.8 | |

| Blood filling volume (ml) | 54 | 74 | 95 | |

| Membrane material | Helixone® | |||

| Housing material | Polypropylene | |||

| Potting compound | Polyurethane | |||

| Sterilization method | INLINE steam | |||

| Application | HD | |||

FX high-flux dialyzers

| FX high-flux dialyzers | FX 40 | FX 50 | FX 60 | FX 80 | FX 100 |

|---|---|---|---|---|---|

| Ultrafiltration coefficient (ml/h x mmHg) | 20 | 33 | 46 | 59 | 73 |

| Clearance: QB: (200ml/min) | |||||

| Urea | 170 | 189 | 193 | 197 | |

| Creatinine | 144 | 170 | 182 | 189 | |

| Phosphate | 138 | 165 | 177 | 185 | |

| Vitamin B12 | 84 | 115 | 135 | 148 | |

| Inulin | 54 | 76 | 95 | 112 | |

| Clearance: QB: (300ml/min) | |||||

| Urea | 250 | 261 | 276 | 278 | |

| Creatinine | 210 | 230 | 250 | 261 | |

| Phosphate | 201 | 220 | 239 | 248 | |

| Vitamin B12 | 130 | 155 | 175 | 192 | |

| Inulin | 81 | 104 | 125 | 142 | |

| Clearance: QB: (400ml/min) | |||||

| Urea | 303 | 362 | 331 | ||

| Creatinine | 262 | 287 | 304 | ||

| Phosphate | 248 | 272 | 284 | ||

| Vitamin B12 | 167 | 190 | 213 | ||

| Inulin | 109 | 133 | 152 | ||

| The in vitro performance data were obtained with QD = 500ml/min: QF = 0ml/min; T=37°C (ISO8637) The ultrafiltration coefficients were maintained using human blood, Hct = 32%, protein content 6% |

|||||

| Effective surface area (m²) | 0.6 | 1.0 | 1.4 | 1.8 | 2.2 |

| Blood filling volume (ml) | 32 | 53 | 74 | 95 | 116 |

| Membrane material | Helixone® | ||||

| Housing material | Polypropylene | ||||

| Potting compound | Polyurethane | ||||

| Sterilization method | INLINE steam | ||||

| Application | HD/HDF/HF | ||||

FX hemodiafilters

| FX hemodiafilters | FX 600 | FX 800 | FX 1000 |

|---|---|---|---|

| Ultrafiltration coefficient (ml/h x mmHg) | 52 | 63 | 75 |

| Clearance: QB: (200ml/min)QF: (0ml/min) | |||

| Urea | 196 | 198 | |

| Creatinine | 184 | 190 | |

| Phosphate | 180 | 184 | |

| Vitamin B12 | 141 | 149 | |

| Inulin | 101 | 110 | |

| Clearance: QB: (300ml/min) QF: (75ml/min) | |||

| Urea | 284 | 289 | 290 |

| Creatinine | 262 | 271 | 280 |

| Phosphate | 254 | 262 | 269 |

| Vitamin B12 | 199 | 209 | 211 |

| Inulin | 150 | 161 | 164 |

| Clearance: QB: (400ml/min) QF: (100ml/min) | |||

| Urea | 351 | 361 | 364 |

| Creatinine | 313 | 328 | 343 |

| Phosphate | 301 | 313 | 325 |

| Vitamin B12 | 229 | 241 | 244 |

| Inulin | 172 | 185 | 188 |

| The in vitro performance data were obtained with QD = 500ml/min: T=37°C (ISO8637) The ultrafiltration coefficients were maintained using human blood, Hct = 32%, protein content 6% |

|||

| Effective surface area (m²) | 1.5 | 1.8 | 2.2 |

| Wall thickness / inner diameter (µm) | 35/210 | ||

| Blood filling volume (ml) | 97 | 118 | 138 |

| Membrane material | Helixone® | ||

| Housing material | Polypropylene | ||

| Potting compound | Polyurethane | ||

| Sterilization method | INLINE steam | ||

| Application | HD/HDF | ||

Related content

1 Bowry, S.K.: Nano-controlled membrane spinning technology: Regulation of pore size, distribution and morphology of a new polysulfone dialysis membrane. In Hemodialysis Technology (eds: Ronco, C., La Greca, G.) Contributions to Nephrology, Vol. 137: 85-94 (2002)

2 Ronco, C., Nissenson, A.R.: Does nanotechnology apply to dialysis? Blood Purification 19: 347-352 (2001)